When it comes to TIG welding, the choice of gas plays a crucial role in ensuring clean, high-quality welds. Unlike other welding processes, TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode to create the weld and the right gas is essential to protect the weld area from contamination.

In this guide, we'll take a closer look at the gases commonly used in TIG welding, how they work and how to choose the right one for your project.

Why is Gas Important in TIG Welding?

TIG welding requires a shielding gas to protect the molten weld pool from contaminants in the air. Oxygen, Nitrogen and Hydrogen can all cause defects like porosity, oxidation, or weakening of the weld. The shielding gas forms a protective envelope around the weld, ensuring a clean and strong bond between materials. Choosing the right gas helps to:

-

Prevent contamination: Ensures a clean weld with no impurities

-

Control the weld puddle: Helps you achieve a smooth and controlled weld

-

Improve weld appearance: Helps achieve a polished, professional look

The Most Common Gases Used in TIG Welding

- Argon

Argon is by far the most common gas used in TIG welding. It’s an inert gas, meaning it doesn’t react with other elements, making it ideal for creating a protective shield around the weld. Argon provides a stable arc, offers good penetration and is effective for welding most materials.

- Helium

Helium is often used in combination with argon to improve arc stability and heat input. While argon provides good shielding properties, helium offers higher thermal conductivity, which allows for deeper penetration and faster welding speeds.

- Argon-Helium Mix

An argon-helium mix combines the benefits of both gases, offering a balance between heat and shielding properties. Typically, a mix of 75% argon and 25% helium is used, but the ratio can vary depending on the material and welding requirements.

- Hydrogen

Hydrogen is sometimes used in very specific cases, primarily for welding high-strength alloys or for certain aerospace and high-temperature applications. It is typically mixed with argon in small quantities (usually less than 5%).

Choosing the Right Gas for Your TIG Welding Project

The choice of gas depends on several factors, including the materials you're welding, the thickness of the workpieces and the desired speed and quality of the weld.

-

For general welding: Pure argon is often sufficient for most applications, especially when working with steel, stainless steel, or aluminium

-

For welding aluminium: An argon-helium mix is often recommended to improve penetration and speed

-

For professional applications: A mixture of argon, helium and sometimes hydrogen may be ideal for high-speed or high-performance welding

If you’re still unsure, consult the TIG welder’s manual or ask our expert fabrication team about the best gas mix for your machine and welding conditions. If you're in need of a reliable and durable TIG welder, check out our selection of machines and accessories such as TIG welding gloves.

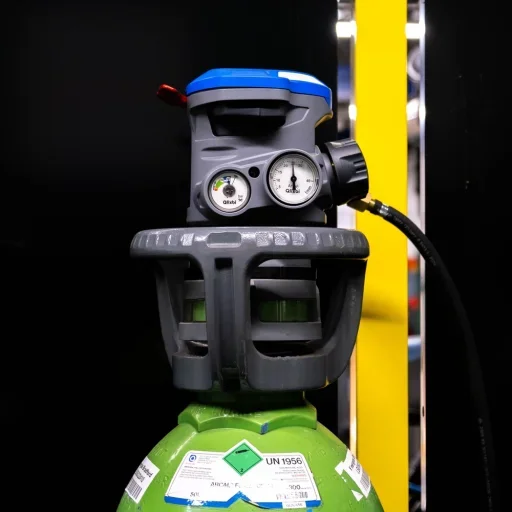

Where to Buy Your TIG Welding Gases

Once you’ve selected the right gas for your welding project, it’s time to buy. You can find can find high-quality TIG welders and welding gases, all with next day delivery, here at Engweld.

Explore more about gas choices with our welding gas selector guide.

Choosing the right gas for TIG welding is essential for achieving strong, clean welds. Argon remains the most common choice for many TIG welding applications, but depending on the material and welding conditions, adding helium or hydrogen to the mix can offer additional benefits. Whether you're welding thin sheet metal or thick alloys, the right shielding gas will ensure your welds are reliable and professional.

For more information about TIG welding, including equipment options, be sure to check out our TIG welders page or browse our full range of welding tools and accessories.