Maximise Your Output: Engweld's Performance Welding Audit and Efficiency Review

Achieve Fabrication Excellence and Bottom-Line Improvement

In today's competitive metal fabrication industry, managing quality and controlling production costs are paramount to success. Engweld offers a comprehensive, data-driven approach designed to identify hidden inefficiencies in your welding operations and transform them into measurable profit improvements.

Our methodology, backed by the extensive global resources of Air Liquide, takes a systematic look at your procedures to ensure you are operating at peak potential.

The Power of Data: Our Analysis Program We leverage the Welding Efficiency Analysis Program (WEAP)—an established methodology developed from over 2,500 customer assessments worldwide—to provide you with unparalleled insight. This sophisticated tool collects and thoroughly examines the critical inputs within your fabrication shop, helping you discover where process adjustments can lead to significant savings.

By partnering with Engweld / Energas, you will gain:

- True Cost-to-Weld: Quantify the hidden expenses of your current operating model.

- Industry Benchmarking: See exactly how your performance measures up against industry averages.

- Quantifiable Savings: Locate and quantify real-world cost drivers you may be overlooking.

What We Analyse

Our expert fabrication consultants will perform an in-depth review of the essential factors influencing your profitability and output quality, including:

| Area of Review | Key Metrics Examined |

|---|---|

| Material Usage | Assessment of your Gas-to-Wire Ratio, MIG and plasma consumable effectiveness, and waste reduction opportunities. |

| Process Control | Analysis of your travel speed, potential for over-welding, and optimisation of welding parameters. |

| Labour Effectiveness | Examination of your operator factor (time spent welding versus preparation/non-welding time) to boost hourly throughput. |

| Quality & Yield | Review of weld quality consistency, rework rates, and development of shop-floor quality standards. |

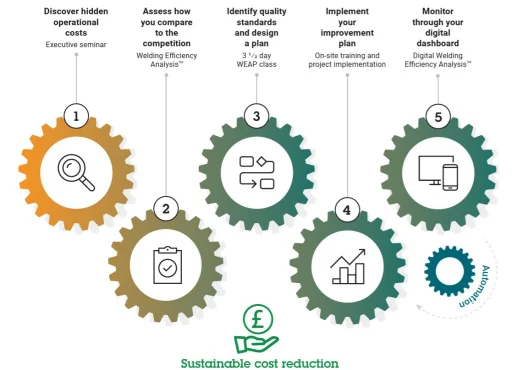

Our 3-Step Continuous Improvement Journey

Our service is not just about identifying problems; it's about providing a sustainable solution that keeps your business competitive. We will guide you through a practical, three-stage improvement plan:

1. Systematic Analysis: Our consultants work on-site to collect data on your existing processes. We use the WEAP database to compare your results against industry leaders, pinpointing areas where the largest impact can be made.

2. Implementation & Training: We collaborate with your team to create a customised Continuous Improvement Plan. This plan includes specific, actionable steps designed to reduce waste and increase productivity by 20% to 40%, often with little or no major capital investment.

3. Monitoring & Sustainability: Following implementation, we help you maintain momentum. We provide dashboard access and comprehensive reporting tools to track your progress, allowing you to sustain savings and monitor the success of your new procedures over time.

Ready to Optimise Your Welding Operations?

Contact us today to schedule your initial consultation and start developing a continuous improvement plan that delivers sustainable, verifiable savings.

We're able to support your welding & fabrication business with a wide range of specialist services including welding machine repair, service & calibration, CP7 & CP47 gas equipment safety checks, welding efficiency analysis through our WEAP program, welding procedures & specifications and NDT testing. We also offer a support scheme to students through welding colleges and educational establishmenets with a bespoke support package.