Non-Destructive Examination (NDE) Services: Quality Assurance Without Damage

Maintain Integrity and Compliance for Critical Welds

Non-Destructive Examination (NDE), often referred to as Non-Destructive Testing (NDT), is a crucial quality control practice that allows flaws and discontinuities to be detected in materials and welded joints without affecting the component's fitness for purpose.

This method of quality verification is mandatory for high-integrity joints (such as those in pressure systems, structural applications, or pipelines) where failure could lead to catastrophic downtime, injury, or costly repairs. NDE is also frequently implemented in high-volume manufacturing as a reliable batch sampling technique.

We can provide comprehensive NDT solutions to ensure your fabricated products meet all required industry codes and standards.

Core Non-Destructive Testing Methods Our comprehensive service portfolio utilises several key NDT techniques to locate both surface and subsurface imperfections.

Visual Inspection (VT) VT is the most common form of Non-Destructive testing (NDT). VT must be performed by trained and qualified personnel to satisfy industry standards.

The most common type of VT qualification within industry is the CSWIP 3-series. All testing should start with VT, as VT is the easiest, quickest and most cost effective method of NDT. the the item fails VT, there is little need to perform any other forms of NDT, until the repaired repairs have been completed.

Ultrasonic testing or UT

Used in various engineering industries as a method to detect defects or discontinuities in materials and/or welds, also used to determine lifecycle ranges of products.

Various types of UT exist, some more advanced than others; conventional UT, phased array, TOFD etc. these are all based on similar technologies but can deliver different results.

UT can be done of most materials,and is often a requirement for many welding standards and codes. UT is also a great tool for reactive and proactive quality control.

Radiograph Interpretation or RT

RT is the process of interpreting the results of a radiograph (X-Ray) of a component. Using a viewing box, and a darkroom the inspector will analyze the film. RT can be completed on most materials, and is often a requirement for many welding standards and codes.

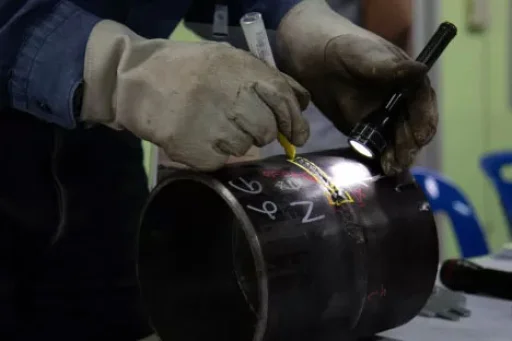

Dye penetrant testing or PT The form of PT in the image is colour contrast Dye Pen, this is one of the most common forms of NDT. Can be used on all materials, but will only defect surface breaking defects.

Very sensitive form of inspection, and will detect defects and discontinuities the human eye cannot see.

Magnetic Particle Inspection or MPI or MT

The form of MPI used in the image in colour contrast MPI, various forms are available and various consumables for each type.

This uses magnetic fields to detect defects and discontinuations, this method is slightly more sensitive than Dye pen, but can only be used on magnetic materials, and will only detect surface and slight subsurface defects (1mm under surface maximum).

One of the most common forms of NDT, also used as a fatigue management tool, good for reactive and proactive quality control.

Request Expert NDT Support

Our welding experts are ready to help you implement the correct testing regimes for your applications.

Would you like to speak with an Engweld Fabrication Expert about your specific NDT or quality control requirements?

We're able to support your welding & fabrication business with a wide range of specialist services including welding machine repair, service & calibration, CP7 & CP47 gas equipment safety checks, welding efficiency analysis through our WEAP program, welding procedures & specifications and NDT testing. We also offer a support scheme to students through welding colleges and educational establishmenets with a bespoke support package.