We're able to support your welding & fabrication business with a wide range of specialist products & services including industrial welding gas mixtures, LPG propane & butane, welding machine repair, service & calibration, CP7 & CP47 gas equipment safety checks, welding efficiency analysis through our WEAP program, welding procedures & specifications and NDT testing. We also offer a support scheme to students through welding colleges and educational establishmenets with a bespoke support package. Contact Us today if you want to speak to our experts about how we can support you today.

Meet our Experts - The Fabrication Excellence Team

For Complex Welding & Metalworking Projects

When your project demands more than just standard solutions, turn to the Fabex team at Engweld and Energas. This elite group of highly skilled engineers and fabricators specialises in tackling the most intricate and challenging welding and metalworking projects.

From unique material requirements to bespoke structural fabrications and precision-engineered components, the Fabex team combines deep technical knowledge with extensive hands-on experience. They're equipped to navigate the complexities that often deter others, delivering innovative, reliable, and high-quality results.

We understand that complex projects require meticulous planning and execution. The Fabex team works closely with clients, offering expert consultation and a collaborative approach to ensure your vision is realised with unparalleled precision and efficiency.

Machine Repairs, Servicing & Calibration

Engweld are approved service agents for all leading brands of welding machines including mig welders, tig welders, arc welders and plasma cutters and associated equipment, offering full service and spares facilities from our main centres, both on or off site. Our expert team of service engineers can also support with warranty information so you can rest assured when purchasing welding machines and plant, you've got the correct level of support needed to keep your welders welding.

Engweld's highly experienced and qualified team of engineers provide a fast turn around to keep our customers working. Working from purpose built service centres located in Hull and Nottingham, offer full warranty, service, repair and spares backup. Find your local Energas branch using our store locator.

We also calibrate welders to BS EN 50504:2008 meeting ISO9000 requirements, either in our workshops or at your premises/site.

Engweld offer dedicated servicing and repair contracts tailored to customers individual needs, with priority call-out, rapid response time, and scheduled servicing and calibration of your welding/cutting machines.

CP7 & CP47 Gas Equipment Safety Checks: Ensuring Full Welding and Cutting Compliance

The safe use of compressed gas equipment is a legal requirement for any workplace. Engweld provides certified inspections to help you meet the compliance demands of the Health and Safety at Work Act 1974 and the Pressure Systems Safety Regulations (PSSR).

Our comprehensive gas equipment safety checks are carried out by our own fully trained and qualified inspectors, who hold certification to both BCGA CP7 and BCGA CP47 standards and operate in strict accordance with HSE guidance (INDG 381).

The inspector is proficient in the theoretical knowledge of equipment functioning, gas properties, and the importance of identifying potential defects and hazards, ensuring your system is safe and compliant.

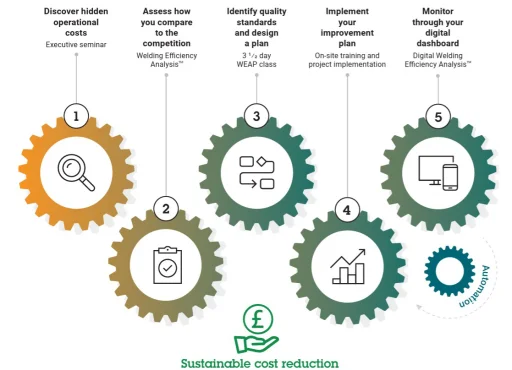

Welding Efficiency Analaysis Program (WEAP)

Achieve Fabrication Excellence and Bottom-Line Improvement.

In today's competitive metal fabrication industry, managing quality and controlling production costs are paramount to success. Engweld offers a comprehensive, data-driven approach designed to identify hidden inefficiencies in your welding operations and transform them into measurable profit improvements.

Our methodology, backed by the extensive global resources of Air Liquide, takes a systematic look at your procedures to ensure you are operating at peak potential.

The Power of Data: Our Analysis Program We leverage the Welding Efficiency Analysis Program (WEAP) an established methodology developed from over 2,500 customer assessments worldwide to provide you with unparalleled insight. This sophisticated tool collects and thoroughly examines the critical inputs within your fabrication shop, helping you discover where process adjustments can lead to significant savings.

Student Support Scheme

We're proud to support welder training and educational establishments with our fabrication excellence student support scheme.

Our support package offers a bespoke branded package of support materials with your logo for your training entity for the following key elements to support welder training and knowledge enhancement for students of all skill levels from new starters through to more advanced:

- Gas cylinder handling

- Gas cylidner transportation

- Gas cylinder storage

- Gas cylinder identification chart

- Easy access to our digital welding gas selector

- Welding workwear & PPE

- Risk management when welding

Welding Procedure & Specification Support: Achieve Certification and Compliance

Ensure Weld Integrity and Regulatory Adherence

For any fabrication business, consistently achieving a high-quality weld and meeting industry standards requires strict control over the joining process. Engweld offers comprehensive technical support and expertise to help you develop, qualify, and document your welding processes to the required codes.

Our team of welding experts and certified partners are here to assist with all your Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR) requirements.

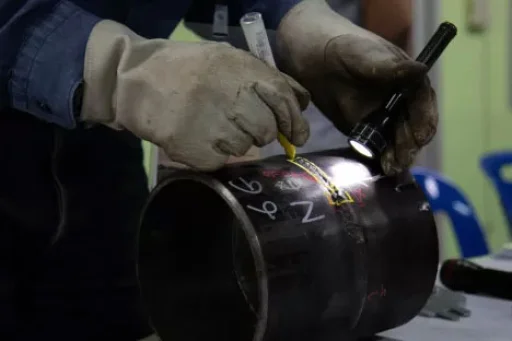

Non-Destructive Examination (NDE) Services: Quality Assurance Without Damage

Maintain Integrity and Compliance for Critical Welds

Non-Destructive Examination (NDE), often referred to as Non-Destructive Testing (NDT), is a crucial quality control practice that allows flaws and discontinuities to be detected in materials and welded joints without affecting the component's fitness for purpose.

This method of quality verification is mandatory for high-integrity joints (such as those in pressure systems, structural applications, or pipelines) where failure could lead to catastrophic downtime, injury, or costly repairs. NDE is also frequently implemented in high-volume manufacturing as a reliable batch sampling technique.

We can support and provide comprehensive NDT solutions to ensure your fabricated products meet all required industry codes and standards.

Centre of fabrication excellence

How the Centre Can Optimise Your Welding Business

The Centre's key objective is to increase your efficiencies, productivity, and safety to reduce overall operating costs and improve profitability. Engweld's expert Fabrication Excellence team are on hand to review your current welding processes and offer suggestions including but not exclusive to:

- Process Optimisation and Cost Reduction

- Enhanced Safety and Best Practice

- Skill and Quality Improvement

- Project implementation

Ready to Optimise Your Welding Operations?

Contact us today to schedule your initial consultation with one of our Energas experts and start developing a continuous improvement plan that delivers sustainable, verifiable savings.