How the Centre Can Optimise Your Welding Business

The Centre's key objective is to increase your efficiencies, productivity, and safety to reduce overall operating costs and improve profitability. Engweld's expert Fabrication Excellence team are on hand to review your current welding processes and offer suggestions including but not exclusive to:

Process Optimisation and Cost Reduction

They can directly review your current operations to find cost savings and efficiency gains:

Weld Optimisation: Our expert team can review your processes and recommend changes to:

Weld parameters: Fine-tuning settings for better results and speed.

Welding gas: Switching to more efficient ARCAL™ gas and using Qlixbi/Exeltop™ cylinders with built-in regulators for quicker changeovers.

Welding consumables: Finding the optimal materials for your specific applications.

Equipment Trials: You can test and try state-of-the-art equipment (like Cobots, MIG/MAG/TIG machines, Plasma Cutters, Pipe Bevellers) on your actual projects to see the true optimised results before you commit to a purchase. Learn more about warranty too.

Reduced Rework: By optimiging the weld and using the right equipment, they aim to reduce the amount of rework required.

Welding Efficiency Analysis Program: You can access this program to showcase and analyse your operations for structured improvement.

Enhanced Safety and Best Practice

We offer knowledge and products to make your workplace safer, which also helps with compliance and employee well-being:

Fume Management: Demonstrations and product availability of Fume extraction systems to protect your welders' health.

Safety Knowledge Transfer: Training and demonstrations on Welding Safety and best practice.

Product Availability: Improving safety through correct PPE and proper Gas cylinder storage, handling and transportation.

Skill and Quality Improvement

They can help you ensure your team and processes meet the highest standards:

Comprehensive Training: We offer welder training to enhance the productivity and quality output of your internal and external parties.

Quality Assurance Support: Providing support for new Weld Procedures and Qualification Records and NDT (Non-Destructive Testing) to help you win and execute higher-spec contracts.

Innovative Tools: Offering training on equipment like the Virtual Reality Welding and Cutting Machines for safe, cost-effective skills development.

Project Implementation

If you have a large project or are looking to implement new technology, we offer:

Welding Project implementation services: Providing hands-on assistance to integrate new processes, equipment (like the Cobot), or procedures into your production line.

In short, the Centre acts as a knowledge transfer, testing, and optimisation hub that directly translates to a more efficient, safer, and ultimately more profitable welding operation for your business.

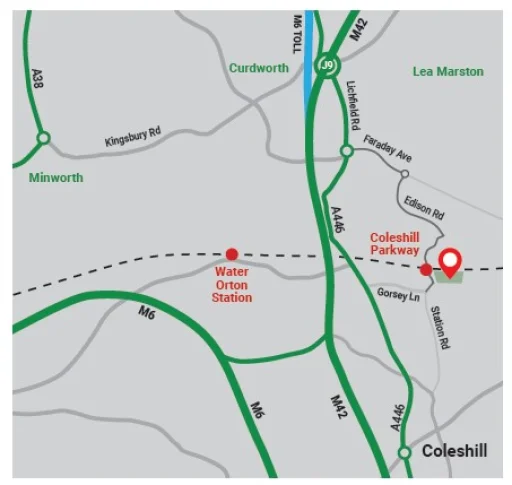

How to find us

Energas Centre of Fabrication Excellence, Station Road, Coleshill, Birmingham B46 1JY What Three Words: discussed.formed.reworked

Are you ready to connect with our Fabrication excellence team to discuss your requirements?

We're able to support your welding & fabrication business with a wide range of specialist services including welding machine repair, service & calibration, CP7 & CP47 gas equipment safety checks, welding efficiency analysis through our WEAP program, welding procedures & specifications and NDT testing. We also offer a support scheme to students through welding colleges and educational establishmenets with a bespoke support package.